-

Session 1 - Revision of Python Programming

-

-

- Join this Course to access resources

-

- Join this Course to access resources

-

Session 2 - Activity - Restaurant food Order System

-

-

- Join this Course to access resources

-

Session 3 - Introduction to Microbit and MakeCode Platform

-

-

- Join this Course to access resources

-

Session 4 - Python Program of Temperature Conversion.

-

-

- Join this Course to access resources

-

Session 5 - Introduction to Temperature Sensor in Microbit

-

-

- Join this Course to access resources

-

Session 6 - Using Two Microbits to Monitor Outdoor Temperatures Remotely

-

-

- Join this Course to access resources

-

Session 7 - Introduction to Microcontrollers and Actuators on Tinkercad

-

Session 8 & 9 - Theft Detection System (Using Arduino + PIR)

-

Session 10 & 11- Plant Watering Using Microbit

- Session 12

- Session 13

- Session 14

- Session 15

- Session 16

-

Session 17 to 20 - Home Automation using Artificial Intelligence and Text to Speech

-

-

- Join this Course to access resources

-

- Join this Course to access resources

Session-15_Build_Your_Own_Flying_Machine_Part_1.pptx

Build Your Own Flying Machine

"The desire to fly is an idea handed down to us by our ancestors who... looked enviously on the birds soaring freely through space."

— Wilbur Wright

This quote by Wilbur Wright, one of the legendary Wright brothers who built and flew the world’s first successful powered aircraft, captures the deep-rooted human aspiration to conquer the skies.

When you're building your flying machine, this quote reminds you that you're part of a long-standing human dream—turning curiosity, imagination, and observation of nature into engineering innovation. From flapping wings to fixed-wing aircraft, and now to drones and flying robots, every flying machine is a tribute to that timeless dream of flight.

Introduction

In this lesson, students will build a scale model of the F‑22 Raptor RC plane using coro sheets and electronic components. This hands-on session introduces basic concepts of aircraft structure, electronics integration, and aerodynamics. It promotes technical confidence, problem-solving, and teamwork by guiding learners through a complete aircraft assembly process.

Prerequisite Knowledge

- Basic understanding of aerodynamics (lift, drag, thrust, and weight).

- Familiarity with servos, motors, and battery functions.

- Basic knowledge of transmitter and receiver systems.

- Comfortable handling tools like glue guns and cutters.

Learning Objectives

- Understand the structure and design of an RC aircraft.

- Learn how to install motors, servos, ESCs, and receivers.

- Identify the importance of CG (center of gravity) and balance in flight.

- Learn pre-flight checks, safety protocols, and trimming techniques.

- Understand the function of elevons and propulsion systems.

Tools & Materials Required

- Coro sheet or Depron for airframe

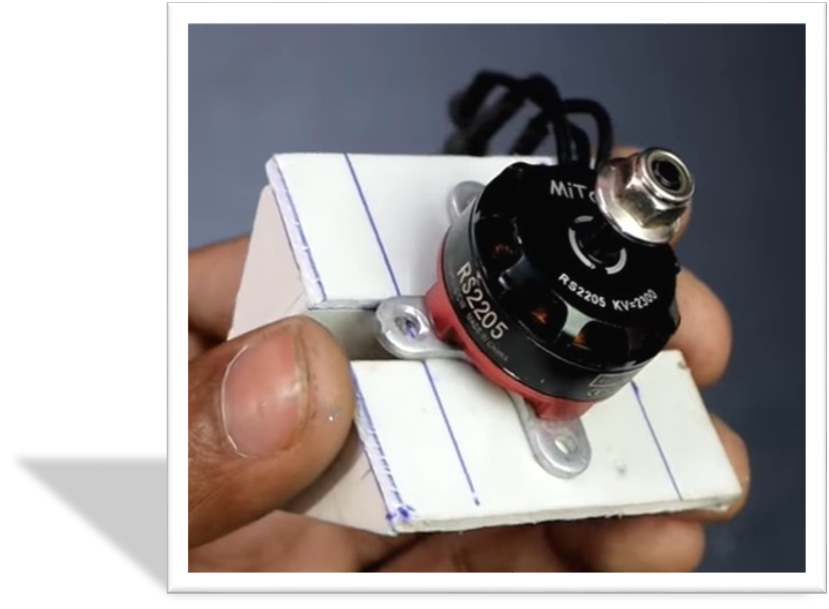

- Brushless outrunner motor (e.g., 2200KV)

- 3-phase ESC (Electronic Speed Controller)

- Propeller (8×4 to 10×6)

- 2 micro servos (9g) and pushrods

- 6-channel radio transmitter and receiver

- LiPo Battery (3S or 4S)

- Velcro, glue gun, CA glue, sunboard (for mount)

- Bamboo sticks/carbon spars for reinforcement

Step-by-Step Procedure

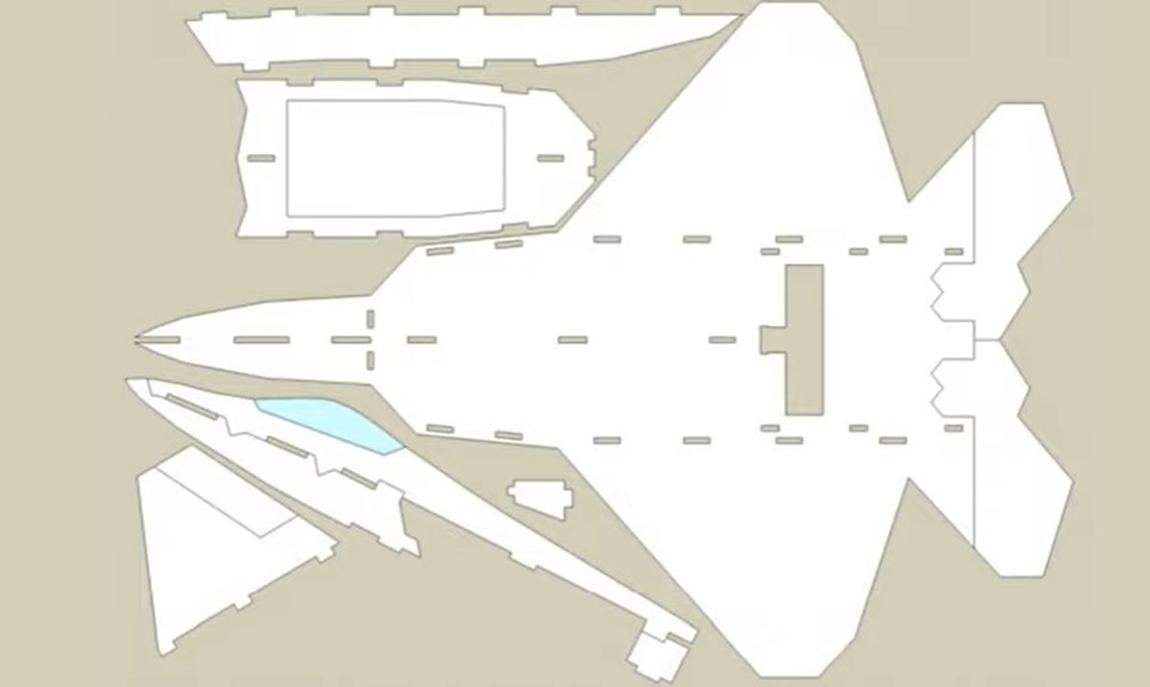

- Start with printing or designing your F‑22 Raptor template and cut the parts from the coro sheet (fuselage, wings, tail).

- Reinforce the wings by inserting bamboo or carbon rods for strength and durability.

- Glue parts together carefully using hot glue, keeping the fuselage aligned to the centerline. Cut wings at a 45° angle for proper aileron movement.

- Prepare a motor mount using sunboard, install the brushless motor securely, and connect it to the ESC.

- Install 2 micro servos for the elevons (combined elevator and aileron), connect pushrods to control horns, and secure wiring.

- Mount the ESC, battery, and receiver in proper channels (1 & 2 for servos, 3 for ESC). Secure with Velcro.

- Ensure the plane's center of gravity is 30% back from the wing’s leading edge. Adjust battery placement for balance.

- Set up control surface mixing on the transmitter for elevons to handle pitch and roll correctly.

- Attach propeller and ensure ESC provides proper power to receiver and motors.

- Perform full pre-flight checks including control directions, motor spin, loose parts, and charge levels before launch.

Outcome

- Students will be able to identify all the parts of the rc plane.

- Students will be able to assemble all the parts of the rc plane.

- Students will get an in hand experience of applying applications of aerodynamics in real life objects.

There are no comments for now.